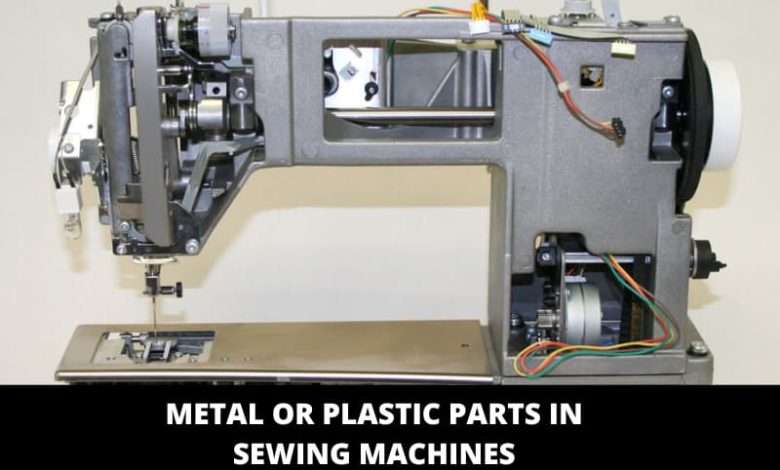

Metal or Plastic Parts In Sewing Machines

In this article you’ll get information about Parts in Sewing Machines. This post may include affiliate hyperlinks for products I would recommend. If you click on a link and purchase something, I could receive a commission. This isn’t a change to the cost you have to pay.

Are you concerned about whether there are parts made of plastic or metal in the sewing machines that are on the list of items to purchase? We’ve all been told by our mothers, friends, or our sewing group circle that we should stay clear of any plastic parts at all costs.

It’s actually not as bad as you imagine (she stated that even though she could imagine her mother scowling and saying to Heaven, “Have I taught her absolutely nothing? !”)

In Part, we’ve been conditioned to be led to believe that sewing equipment that is made of metal rather than plastic is much less efficient.

It is due to the fact that sewing equipment was built out of metal for decades. We are aware of this because we were taught to do sewing on powerful machines, which were the possessions of our grandparents and parents.

Quick Overview Of Parts In Sewing Machines

If we didn’t get the same amount of value from our purchase, it’s likely that we’ve had a scam, right? Actually, no.

“We’re getting exponentially better efficiency, automation, and technology out of today’s plastic machines than our parents and grandparents did out of their all-metal sewing machines.”

Be aware, however, that for an entry-level personal sewing device, you’re likely to struggle with staying clear of plastic. The majority, if not all, with the help of the plastic companies make shells of sewing machine nowadays. The interior components attract more attention rather than the outer shells.

Metal is certainly likely to last longer than plastic, but the lifespan of plastic is something to be snickering about, either. If plastic wasn’t so long-lasting as a material and we weren’t at such a ruckus over the state of our garbage or be as concerned about getting out of using those small plastic bags for grocery shopping that claim to require 500 years to decay.

There are some advantages to plastic over metal as well. It doesn’t rust. It’s more pliable to create shapes in the manufacturing process, is lighter, and weighs much less than steel. This isn’t only any plastic here, and neither is it a cheap one. The plastic that is used for the majority of sewing machines is also the same plastic that is used to create football helmets. This is a plastic designed to endure up to tons of abuse.

Technology provides a huge range of possibilities for producers in all sectors to improve their products by making your products user-friendly and efficient, and more useful. If you also look something like that, then go for the brother sm3701 reviews.

Guide In Depth Of Parts In Sewing Machines

Do you think of what women from the 19th century might think if they witnessed an individual using the machine with lighting? Buttons that you can push to choose among hundreds of stitches?

Technology comes with a cost, and that’s why it’s an endless production process. Consumers are always looking for technological advancements and improvements to products that are larger, faster, better, and more efficient! As technology advances, cost increases. When costs – and prices rise, for consumer’s, companies need to come up with ways to cut expenses. Hello, plastic!

(That sort of creates the impression that it’s our fault, but that’s not the way things are!

For sewing equipment, this plastic has slipped into the first Part of the machine before moving on to another. At first, plastic replaced few of the knobs on the outside. Then, the outer shells were made with plastic. In certain cases, certain interior components are being transformed into plastic.

Here, some more!

That’s why plastic is to be credited for our ability to achieve some amazing capabilities from these sewing machines for the smallest amount of money.

Yes, I did say relatively very little, and here’s why. My father paid around 250 dollars for my mom’s 1973 Viking sewing machine when it was brand new.

You can’t buy an identical product in 2010 for the exact same price that you paid in 1973. It is true that using an inflation calculator, an item that cost you $250 in 1973 could cost $1229.23 in current dollars. Eek!

Conclusion

What we really need to search is whether the sewing machine made with metals or plastic. Our parents had 20, 30, forty, or even more of their sewing machines. What if we can only get five years?

I’m a certified accountant and think, “well, that $350 I spent spread over five years equates to $5.80 per month”. That’s less than what I pay at Starbucks during the week without blinking an eye.